Evaporation Residue Testing convenience store|100 degree evaporation procedure : member club Solids, residue on evaporation at 105°C, total, I-3750-85 (mg/L): 00500. 1. Application. 1.1 This method may be used to determine the total-solids concentration of any natural or treated water . 5 dias atrás · Benfica e Sporting procuram hoje ‘descolar’ um do outro na liderança da I Liga portuguesa de futebol, num dia em que também o FC Porto entrará em campo, .

{plog:ftitle_list}

Get location information for Scotiabank branches and ABMs across Canada. ABA number: 026002532 Institution number: 002 SWIFT code: NOSCCATT. Branch &. ABM Locator. .

residue on evaporation method

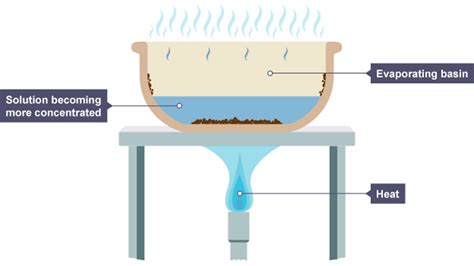

Summary of method. 2.1 A volume of filtered sample that will yield less than 200 mg residue is evaporated just to dryness on a steam bath. The residue is dried at 105°C for 2.0 h, cooled in .This analysis determines the mass of the residue left behind when the water in the sample is evaporated at different temperatures.Gravimetric determination of NVR content measures solvent purity/surface residues to ensure quality and process efficiency. Non-Volatile Matter determination involves evaporating the .

Solids, residue on evaporation at 105°C, total, I-3750-85 (mg/L): 00500. 1. Application. 1.1 This method may be used to determine the total-solids concentration of any natural or treated water .

non volatile residue testing

100 degree evaporation residue

3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997). Material may be accepted but shall not be rejected as failing to meet specifications containing requirements for determination of residue by distillation, on data obtained by evaporation. The mechanism of the different emulsifiers on asphalt binders and their evaporation residue is explored at a microscale to help us to understand emulsified asphalt binder and its evaporation .Evaporation Residue Tester can test the dissolving-out amount of test sample soaked in specified liquid. Skip to main content [email protected] 1-877-884-8378 . Online Store ; News & Articles. News ; Articles ; Contact ; .

The bottom line? While our eyes see nothing wrong, the concealed reality of particulate contamination poses grave unseen risks to downstream production and product functionality. Only advanced testing delivers the truth about the cleanliness of precision components after intricate cleaning preparation. Going Deeper - Nonvolatile Residue - NVR .

I SO 5277, Aromatic hydrocarbons - Determination of residue on evaporation. 1) I SO 5789, Fluorinated hydrocarbons for industrial use - Deter- mina tion of non-vola Me residue. 3 Principle Evaporation of a test portion on a water bath, and drying of the residue, if any, in an oven at 110 + 2 OC to constant mass.This International Standard specifies a procedure of test for high temperature (105 °C) evaporation residue in DME used as fuel by the mass analysis method. This procedure is applicable to determine the amount of high temperature (105 °C) evaporation residue up to the value specified in ISO 16861.This International Standard specifies a method for the determination of the amount of carbon residue, in the range 0,10 % (m/m) to 30,0 % (m/m), left after evaporation and pyrolysis of petroleum products under specified conditions. NOTE 1 The carbon residue value serves as an approximation of the tendency of petroleum products to

3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997). Material may be accepted but shall not be rejected as failing to meet specifications containing requirements for determination of residue by distillation, on data obtained by evaporation.Gum Test Apparatus measures evaporation residue in aviation fuels, motor gasoline, and other volatile distillates as per standard test procedures. The HGT 915 uses air evaporation, while the HGT 917 offers the versatility of either air or steam evaporation. Both are capable of testing three 100ml samples simultaneously.

the momet the world's first orchid moisture meter

This test method covers the determination of non-volatile matter, that is, residue on evaporation, in solvent extract from aerospace components, using a rotary flash evaporator. The summary of the test method, the apparatus for testing, reagents and materials for testing, and procedure for testing are all presented in details.

The Japanese Food Sanitation Act designates the evaporation residue test as a specification for plastics that intended to contact with foods. The test conditions and migration limits for oils and fatty foods were considered on the basis of the results obtained from the evaporation residue test according to the Japanese Act and the overall migration test into olive oil according to . As the residue left by the distilled alcohol seems to be "highly non volatile" rather than acting on the distillation, a long column should prevent escape of aerosol. A 20 cm vigreaux is certainly short, especially if nested on flask of the liter scale! $\endgroup$ The NaOH they add to it is to prolong shelf life. And the reaction by which sodium hypochlorite is reduced to sodium chloride consumes protons, producing even more hydroxide, so it's indeed possible that residual alkali is causing the irritation the OP is describing.astmd693422-Standard Test Method for Residue by Evaporation of Emulsified Asphalt- 1.1This test method covers the quantitative determination of residue in emul . HOME; PRODUCTS. . Documents sold on the ANSI Standards Store are in electronic Adobe Acrobat PDF format.however some ISO and IEC standards are available from Amazon in hard copy format.

Emulsified asphalt is the oil-in-water (O/W) emulsion formed by heating and melting asphalt, dispersing it as fine particles in an aqueous solution containing emulsifiers and their additives under mechanical stirring, which is liquid at room temperature (Gorman et al., 2004).It can be seen that asphalt is the most important component of emulsified asphalt, generally .1.1 This test method covers the determination of the amount of carbon residue (Note 1) left after evaporation and pyrolysis of an oil, and is intended to provide some indication of relative coke-forming propensities.This test method is .

It is seen that the density of anionic emulsified asphalt evaporation residue decreases with the anionic emulsifier contents, while the trend between cationic emulsified asphalt evaporation residue and cationic emulsifier is not obvious, but the density of C3.0 is obviously larger than C0.6 and C1.7. The term “SAP” in the context of acetic acid glacial testing likely refers to the “Saponification Value” or “Saponification Acid Value.” The Acetic Acid Glacial Testing Procedure (SAP) saponification value is a measure of the average molecular weight of all the fatty acids present in a substance. It is often used in the analysis of fats and oils. We found that during evaporation, droplets on the tested surfaces first shrink in height (constant contact radius mode) and then in diameter (constant contact angle mode) to form a thin liquid film, leaving behind residues of different types on the order of micrometers, as illustrated in Fig. 1.We either obtain a single residue, most likely a thin film or droplet, or .

Fire debris can be tested for ignitable liquids using gas chromatography mass spectrometry. This test can determine the classification of the ignitable liquid. Source: Crime Scene and Evidence Collection Handbook. Bureau of Alcohol, Tobacco, Firearms and Explosives, 2005. interFIRE. "Evidence Sampling for Ignitable Liquids Testing."

Solids, residue on evaporation at 105°C, total, gravimetric Parameter and Code: Solids, residue on evaporation at 105°C, total, I-3750-85 (mg/L): 00500 1. Application 1.1 This method may be used to determine the total-solids concentration of any natural or treated water or industrial waste. 1.2 Total residue represents the sum of both

3.1.1 carbon residue, n—the residue formed by evaporation and thermal degradation of a carbon containing material. 3.1.1.1 Discussion—The residue is not composed entirely of carbon but is a coke that can be further changed by carbon pyrolysis. 4. Summary of Test Method 4.1 A weighed quantity of sample is placed in a glass vialMeasure evaporation residue in aviation fuels, motor gasolines, and other volatile distillates in accordance with ASTM D 381, ISO 6246, EN 5 and IP 131 test methods. The HGT 915 uses air evaporation, while the HGT 917 offers the versatility of either air or steam evaporation.

1. Calculate the percentage of residue for each sample, as follows: Residue, % = 4 × (M a -M b) where: M a = Weight of the container and asphalt emulsion residue in grams, and M b = Tare weight of the container in grams. F. REPORTING OF RESULTS Report the percentage of residue by evaporation as the average of the three results. G. PRECAUTIONSCO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups For example, evaporation of liquid into air is strongly affected by the insulating properties of the air itself, so for these experiments the process was observed in a chamber with only the liquid and vapor present, isolated from the surrounding air. Then, in order to probe the effects right at the boundary between the liquid and the vapor, the . Cooling and weighing the residue: After evaporation, the dish is allowed to cool to room temperature in a desiccator and then re-weighed to determine the weight of the nonvolatile residue. Calculation: The nonvolatile matter content is calculated by dividing the weight of the nonvolatile residue by the weight of the original sample and .

100 degree evaporation procedure

webUse Google Slides to create beautiful presentations together. Share, collaborate, and .

Evaporation Residue Testing convenience store|100 degree evaporation procedure